Researchers mix graphene and sulphur for battery breakthrough

April 29, 2019 | 11:26

Companies: #chalmers-university-of-technology

Researchers at Chalmers University of Technology in Sweden claim to have made a breakthrough in the development of lithium sulphur batteries, offering a fivefold increase in energy density over today's lithium-ion, using a graphene sponge.

Graphene, a honeycomb lattice of carbon measuring just one atom thick, has been positioned as a miracle material for a range of technologies - including batteries, where it has been available on the market since 2012. Researchers at Chalmers University of Technology, though, have now found a way to use a graphene sponge to help bring energy-dense lithium sulphur batteries to market - potentially boosting the lifespan of future mobile devices fivefold.

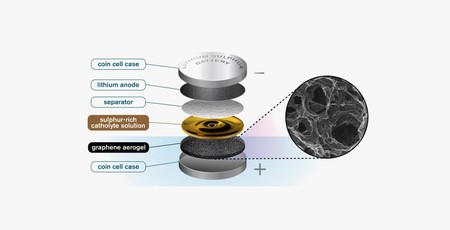

Where a traditional battery is made up of four key parts - the anode, cathode, electrolyte, and a separator so the anode and cathode electrodes don't make direct contact - the researchers' work sees the cathode and electrolyte combined into a single liquid dubbed a 'catholyte'. Previously, though, this combination - while offering reduced weight, faster charging, and improved capacities - proved unreliable.

The solution: The insertion of a layer of graphene aerogel. 'You take the aerogel, which is a long thin cylinder, and then you slice it – almost like a salami. You take that slice and compress it, to fit into the battery,' explains lead researcher Carmen Cavallo. 'The porous structure of the graphene aerogel is key. It soaks up a high amount of the catholyte, giving you high enough sulphur loading to make the catholyte concept worthwhile. This kind of semi-liquid catholyte is really essential here. It allows the sulphur to cycle back and forth without any losses. It is not lost through dissolution – because it is already dissolved into the catholyte solution.'

The redesigned battery could, the researchers claim, scale up to a theoretical maximum energy density of 1,500 watt-hours per kilogramme - a considerable boost over the 350 watt-hours per kilogramme available from perfect lithium-ion batteries. 'Furthermore, sulphur is cheap, highly abundant, and much more environmentally friendly,' adds Professor Aleksander Matic. 'Lithium sulphur batteries also have the advantage of not needing to contain any environmentally harmful fluorine, as is commonly found in lithium ion batteries.'

The prototype created by the research team shows an 85 percent capacity retention after 350 charge-discharge cycle, proving considerably more reliable than previous lithium sulphur efforts. The team, however, warns that there is a long road to commercialisation still ahead: 'Since these batteries are produced in an alternative way from most normal batteries,' explains Professor Matic, 'new manufacturing processes will need to be developed to make them commercially viable.'

The team's work is published in the Journal of Power Sources under open access terms and a Creative Commons licence.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.