New techniques boost 3D printing speed a hundredfold

January 24, 2019 | 11:39

Companies: #university-of-michigan

Researchers at the University of Michigan have found a way to speed up the act of 3D printing by two orders of magnitude, coming up with a system which can produce objects in minutes rather than hours.

3D printing - the act of using a computer-controlled system to turn a material, typically threads of solid plastic or special liquid polymers, into three-dimensional objects - promises much: Using 3D printers, it's possible to produce objects that would previously have required expensive and large-scale injection moulding techniques. Industrial 3D printers can cut out miles of shipping, allowing for objects to be created on-demand close to the end user; personal 3D printers, meanwhile, let you create objects right at your desk.

In all cases, though, there's a problem of scale: 3D printers are, like the earliest 2D printers before them, slow. Printing something as simple as a small toy can take multiple hours, meaning they're ill-suited to rapid production or medium-scale production - unless, as Associate Professor Timothy Scott explains of the inspiration behind his research, you've got 'hundreds of machines' all running in parallel.

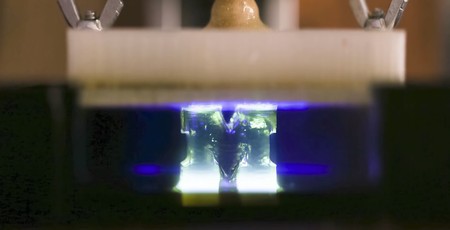

Scott's solution, developed with Professor Mark Burns, is based on liquid resin printing: A specially-developed resin material is hardened on exposure to ultraviolet light. Rather than building it up a 2D slice or 1D line at a time, as with traditional resin or solid-filament printers, the secret lies in a new technique for hardening 3D sections in a single shot - making it, Burns claims, 'one of the first true 3D printers ever made'.

The team's approach replaces previous designs which use an oxygen-permeable window between the light source and the resin to halt solidification and prevent the hardened resin from sticking with a second light and a newly-developed resin chemistry, which allow for a bigger gap between window and object and a corresponding increase in production rate. Using the new system, the researchers claim, it's possible to print up to a hundred times faster than current vat-based resin printers, and to create objects which are stronger and more durable than either resin- or filament-based printers.

The pair's work, which is the subject of three patent applications by the University of Michigan, has been published as open access in the journal Science Advances.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.