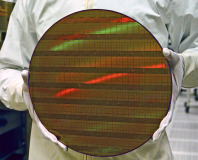

Intel has announced planned upgrades to its manufacturing facilities in the US, along with the opening of a brand-new fab in Oregon, as part of the company's commitment to producing 22nm processors.

According to chief executive Paul Otellini, the planned investment of between $6 billion and $8 billion 'reflects the next tranche of the continued advancement of Moore's Law and a further commitment to invest in the future of Intel and America.'

Otellini went on to claim that 'the most immediate effect of our multi-billion-dollar investment will be the thousands of jobs associated with building a new fab and upgrading four others, and the high-wage, high-tech manufacturing jobs that follow'

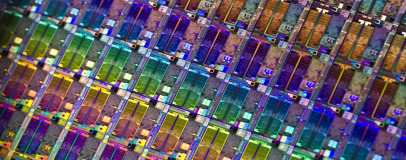

While the temporary 6,000 to 8,000 construction jobs associated with the Oregon project and the creation of between 800 to 1,000 permanent high-tech posts will be certainly welcomed, it's the technology that's the important thing - and Intel will be using the new and upgraded manufacturing facilities to produce its 'Ivy Bridge' processors, 22nm chips due to hit the mass market in 2011.

While firm details about Ivy Bridge have yet to appear, Intel is promising that the small process size will mean 'sleeker device designs, higher performance, and longer battery life at lower costs,' suggesting that the first 22nm processors will be aimed at the mobile and small-form factor markets.

Sadly, the new Oregon plant won't be getting in on the act for a while, with Intel stating that the D1X fab is 'scheduled for R&D start-up in 2013.'

Do you think that Intel's investment in 22nm technology is the way to go, or could the company have saved itself a whole lot of cash by farming the fabrication out to third parties? Share your thoughts over in the forums.

According to chief executive Paul Otellini, the planned investment of between $6 billion and $8 billion 'reflects the next tranche of the continued advancement of Moore's Law and a further commitment to invest in the future of Intel and America.'

Otellini went on to claim that 'the most immediate effect of our multi-billion-dollar investment will be the thousands of jobs associated with building a new fab and upgrading four others, and the high-wage, high-tech manufacturing jobs that follow'

While the temporary 6,000 to 8,000 construction jobs associated with the Oregon project and the creation of between 800 to 1,000 permanent high-tech posts will be certainly welcomed, it's the technology that's the important thing - and Intel will be using the new and upgraded manufacturing facilities to produce its 'Ivy Bridge' processors, 22nm chips due to hit the mass market in 2011.

While firm details about Ivy Bridge have yet to appear, Intel is promising that the small process size will mean 'sleeker device designs, higher performance, and longer battery life at lower costs,' suggesting that the first 22nm processors will be aimed at the mobile and small-form factor markets.

Sadly, the new Oregon plant won't be getting in on the act for a while, with Intel stating that the D1X fab is 'scheduled for R&D start-up in 2013.'

Do you think that Intel's investment in 22nm technology is the way to go, or could the company have saved itself a whole lot of cash by farming the fabrication out to third parties? Share your thoughts over in the forums.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.