Shin-Etsu Chemical, a company perhaps best known in these circles for its thermal grease products, has announced an innovation in LED technology which promises to boost brightness without reducing lifespan.

Forming the heart of many a case lighting project, as seen in our series on case lighting, LEDs are cheap and easy to use. They also generate far less heat than traditional lighting systems, although the brighter models can require some form of heatsink to stay cool.

Sadly, they're not perfect: despite promised lifespans of thousands of hours, various issues - thermal cycling, gas permeation and others - conspire to send LEDs dark before their time.

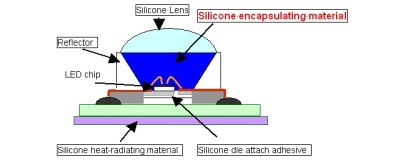

Shin-Etsu's solution to the problem is a new silicone encapsulating material which it claims boosts reliability while ensuring superior brightness through increased transparency and a lower refractive index than other encapsulating materials.

Designed for use with high-brightness LEDs (HBLEDs) often used in case mods and home lighting systems, the new encapsulating material is claimed to have significantly reduced gas permeability over previous materials. The result, Shin-Etsu claims, is a reduction in corrosion of peripheral materials that can lead to reduced light output over time and even premature failure.

The announcement comes as Shin-Etsu looks to increase its presence in the HBLED market, having recently also announced new heat-radiation die-bond materials, lens reflectors, reflector materials and moisture-proof insulating materials. Clearly, the company isn't just targeting the enthusiast: its products are finding their way into commercial home lighting products and as backlights on TVs and laptops.

Shin-Etsu has yet to confirm when LEDs based around the new material, known as the KER-7000 series, will be available to buy.

Forming the heart of many a case lighting project, as seen in our series on case lighting, LEDs are cheap and easy to use. They also generate far less heat than traditional lighting systems, although the brighter models can require some form of heatsink to stay cool.

Sadly, they're not perfect: despite promised lifespans of thousands of hours, various issues - thermal cycling, gas permeation and others - conspire to send LEDs dark before their time.

Shin-Etsu's solution to the problem is a new silicone encapsulating material which it claims boosts reliability while ensuring superior brightness through increased transparency and a lower refractive index than other encapsulating materials.

Designed for use with high-brightness LEDs (HBLEDs) often used in case mods and home lighting systems, the new encapsulating material is claimed to have significantly reduced gas permeability over previous materials. The result, Shin-Etsu claims, is a reduction in corrosion of peripheral materials that can lead to reduced light output over time and even premature failure.

The announcement comes as Shin-Etsu looks to increase its presence in the HBLED market, having recently also announced new heat-radiation die-bond materials, lens reflectors, reflector materials and moisture-proof insulating materials. Clearly, the company isn't just targeting the enthusiast: its products are finding their way into commercial home lighting products and as backlights on TVs and laptops.

Shin-Etsu has yet to confirm when LEDs based around the new material, known as the KER-7000 series, will be available to buy.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.