Researchers develop cold-soldering substance

April 26, 2016 | 12:20

Companies: #iowa-state-university #research

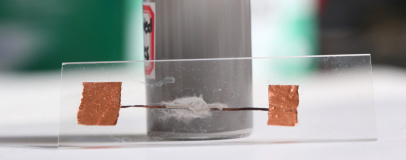

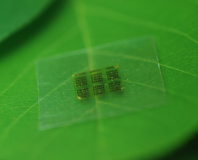

Researchers have developed an alternative to soldering which can bond components together without the need to apply heat, using micro-scale liquid-metal particles.

A team led by Iowa State University Professor Martin Thuo has developed a substance which allows components to be soldered together without the need to apply any heat. Created following research into methods to stop liquid metals from returning to solid form even at temperatures below the metal's melting point, a process known as undercooling, the material takes the form of tiny droplets of liquid metal sheered using a rotary tool within acidic liquid them oxidised to create a capsule the size of a red blood cell.

'We wanted to make sure the metals don’t turn into solids,' Thuo explained of the process, 'and so we engineered the surface of the particles so there is no pathway for liquid metal to turn to a solid. We’ve trapped it in a state it doesn’t want to be in.' That turns out to be handy for practical purposes as well as bragging rights: the team has demonstrated using the capsules to solder together metals without the application of heat, and to repair damaged metal surfaces similarly.[/i]'

Sadly, as with many research projects, there's no immediate roadmap to commercialisation: the team is actively investigating the technique for mechanical reliability and electrical conductivity compared to traditional hot soldering, though it is confident enough it has already applied for a patent and is actively proceeding with development under the start-up SAFI-Tech.

The team's research is available in the journal Nature.

A team led by Iowa State University Professor Martin Thuo has developed a substance which allows components to be soldered together without the need to apply any heat. Created following research into methods to stop liquid metals from returning to solid form even at temperatures below the metal's melting point, a process known as undercooling, the material takes the form of tiny droplets of liquid metal sheered using a rotary tool within acidic liquid them oxidised to create a capsule the size of a red blood cell.

'We wanted to make sure the metals don’t turn into solids,' Thuo explained of the process, 'and so we engineered the surface of the particles so there is no pathway for liquid metal to turn to a solid. We’ve trapped it in a state it doesn’t want to be in.' That turns out to be handy for practical purposes as well as bragging rights: the team has demonstrated using the capsules to solder together metals without the application of heat, and to repair damaged metal surfaces similarly.[/i]'

Sadly, as with many research projects, there's no immediate roadmap to commercialisation: the team is actively investigating the technique for mechanical reliability and electrical conductivity compared to traditional hot soldering, though it is confident enough it has already applied for a patent and is actively proceeding with development under the start-up SAFI-Tech.

The team's research is available in the journal Nature.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.